Egeli Motor Engine Renewal and Reconditioning

Gürpınar Mah 7004/3 Sok. No:13/6A Yaka Mevkii Pınarbaşı / İZMİR Tel : 0232 479 1527 - 0232 479 1528 - GSM: 0530 461 7249

WHAT WE DO ?

Our company fully covers the engine reconditioning workmanship of all diesel, gasoline and LPG powered engines.

In addition to the standart equipment we use as part of our business, we provide minimum error and maximum performance with cost-effective prices using our lathe and other support equipment. Furthermore, our company is the only company in our region that provides Cylinder Liner Pressing with nitrogen gas.

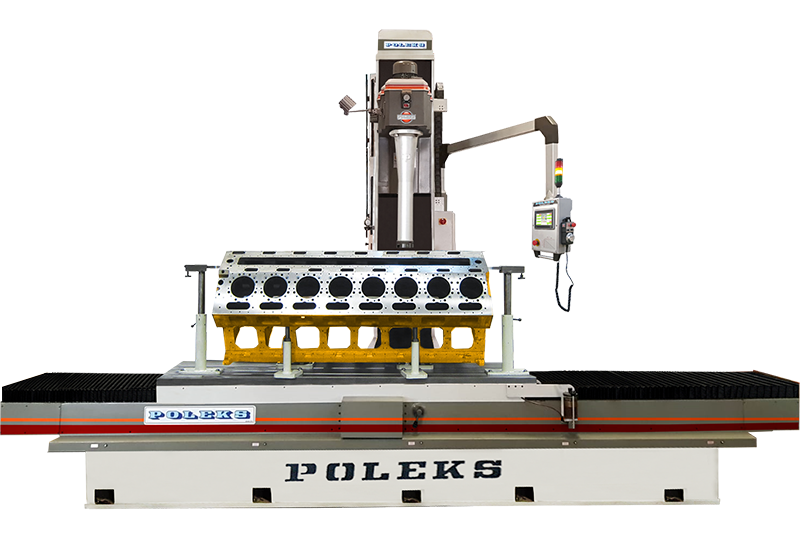

Our company has the ability to hone the surfaces of 265 cm long blocks. Also, we are able to do the crankshaft grinding work up to 295 cms.

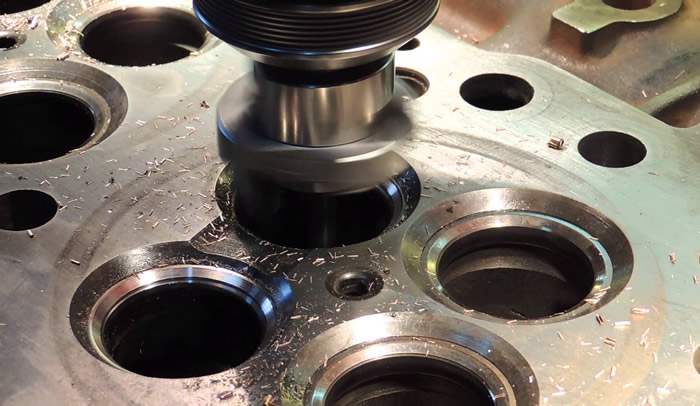

OUR SERVICES

We provide these services under the expertise of our company:

- Crankshaft Grinding And Polishing

- Main Bearing Nner Cap Boring

- Crank Pin Bearing Inner Cap Boring

- Bushing Rod Boring

- Liner Press And Nitrining

- Reconditioning, Honing And Surface Grinding

- Surface Roughness Test

- Cylinder Head Revision

- Socket Honing And Grading

- Guide Production And Reaming

OUR QUALITY POLICY

In our services, we pay utmost importance to provide unconditional customer satisfaction, to establish a quality management system and apply it to greatest efficiency, and to improve upon our own standarts in a daily basis.

With 49 years of experience in our field, we introduce the finest quality work, utilising our team of qualified mechanics which consist of 11 master technicians and 5 service vehicles in order to comply with the requirements of our customers in the best and fastest possible manner. We provide highest quality in all our craftsmanship thanks to our delicate workshop equipment and our professional technicians who are experts in their fields. We are going to deliver our services without compromising on quality in the future.

WHO ARE WE ?

Our company is established in 1977 in Canakkale, Turkey. Our company moved to Izmir, Turkey in 1986 and we continue our services until then. In our 49 years of service history, by following the latest technological developments in world-wide produced gasoline and diesel-powered engines, we provided our own development, reaching the capacity to comply with the requirements of the ever-developing sector.

Staying in correspondance with the manufacturers on new generation engine technologies, our company provided significant improvements in our field on application of the improved materials on engines. Instead of obtaining the company personnel from the market, our company has the ability and system to provide in- service training to our staff to the highest quality and service standarts.

Since 2004, our TSI (Turkish Standarts Institue) and SCC (Service Competence Certificate) certified company continues its services with a staff of 11 technicians and 5 support vehicles in a 400 squaremeters indoor area. Without compromising from quality and trust, we continue our services in a righteous understanding.

CRACK TEST

In order to detect the cracks on engine and cylinder head (Malfunction of compression leakage) , a Crack Test is carried out, by applying heat and pressure.

The part to be tested is taken to the crack detection bench and heated to 80 centigrades and applied pressure.

ENDOSCOPY

The term “endoscopy” is commonly used in medicine. The equipment that enables the visual inspection on normally nonvisible parts is called Endoscopy.

With endoscopy, by accessing the engines from injectors, we are able to track the malfunctions in the inner parts of cylinders..

WASHING

Vehicle motors are prone to rusting. Being suspected to constant heat , oil steam and dust from fans, when contacted with water, the rusting occasionally takes place.

With high concentrated, water-based and solvent-free engine cleaning product, the engine is purified of all oil and dirt..

EN

EN TÜRKÇE

TÜRKÇE